Introduction

Reinforced concrete structures are widely used in construction projects, and the bonding properties between the reinforcement and concrete play a crucial role in the safety and durability of these structures [1-3]. However, steel bars are prone to rusting in wet environments, leading to a decline in bonding performance that interferes structural integrity. Recycled concrete is an environmentally friendly building material made from recycled waste concrete that has good sustainability and environmental benefits [4-6]. Domestic scholars have gained some experience in this research area, promoting the development of the domestic construction industry. For example, in the study of recycled concrete, Li Weina conducted empirical research on its mechanical properties. The study identified two factors that can affect its compressive strength: the properties of the original material and the combustion temperature. After heating, the mass loss rate of recycled concrete increases, and the color change becomes more significant. The compressive strength is inversely proportional to these two influencing factors, increasing and decreasing accordingly. The empirical results indicate that the final slip increase is 9.5%. This finding provides a reference for similar engineering studies and offers data support for understanding the actual mechanical properties of recycled concrete [7]. Li and Wu tested the compressive strength of recycled concrete by varying the method of mineral mixing, and found that this property increases accordingly. With a 1% increase in wollastonite content, its compressive strength can increase by 1.36 MPa. However, this proportional relationship is not continuous. When the amount of wollastonite reaches a certain level, its ability to withstand pressure decreases. As the steel fiber parameters increase, the compressive strength first increases and then decreases. However, it is evident that this influence is quite prominent. Therefore, adjusting the steel fiber content to affect the compressive capacity can help meet the actual requirements [8]. In the early 1990s, foreign scholars Henrichshen et al. studied the stress-strain curve of recycled concrete, and no differences were observed in the shape of the constitutive curve between natural concrete and recycled concrete, which laid a foundation for subsequent research on the curve change of recycled concrete [9]. In summary, both domestic and foreign scholars have conducted relatively mature research in this area, including studies on the change of the constitutive curve. However, there is still much space for further research on steel corrosion and the bonding properties of concrete. On the basis of this gap in research, an in-depth study on the bonding pressure performance under different degrees of rust (0%, 1%, 2%, and 4%) is conducted via a combination of qualitative and quantitative methods, the variation rules are obtained, which will lay a foundation for practical engineering applications.

Recycled concrete preparation

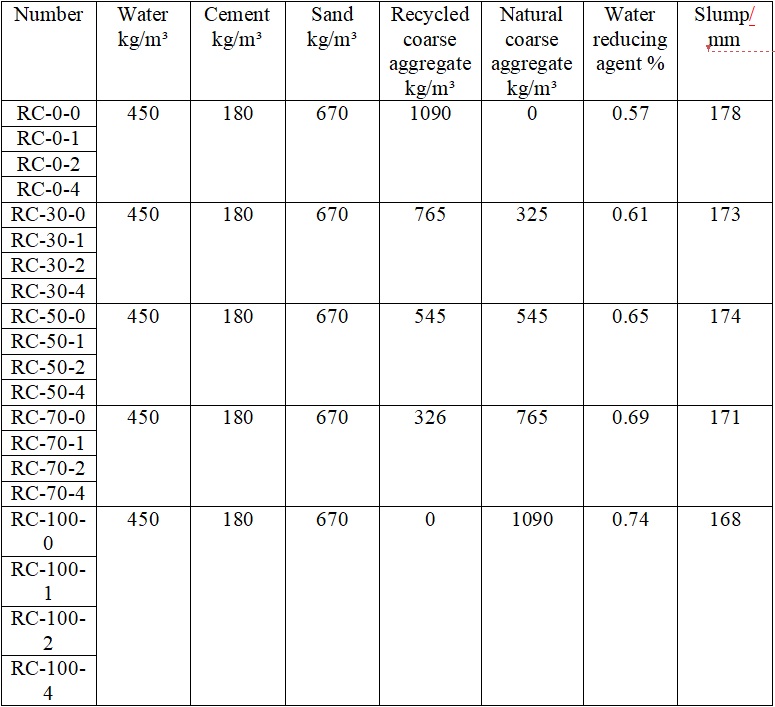

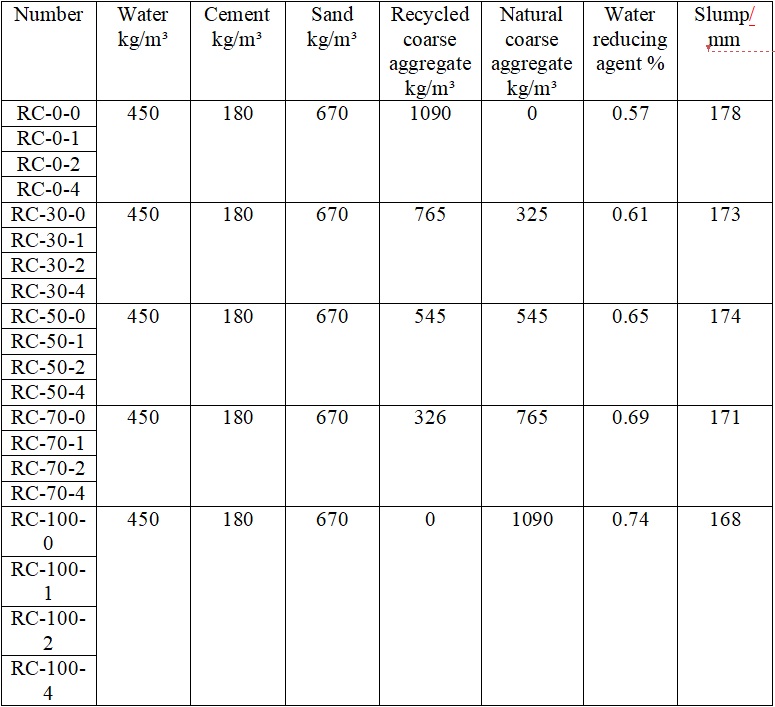

Currently, the production of recycled concrete must be carried out in strict accordance with specification standards because the origin of recycled coarse aggregate and the mechanical crushing process vary, and the performance of recycled aggregate in aspects such as water absorption, porosity, and other indicators can differ significantly, and it is necessary to determine the appropriate proportions for preparing recycled concrete. The goal was to optimize the mix proportion of concrete. First, the relevant mix proportions for conventional concrete are set. Then, the water absorption of recycled concrete is comprehensively considered. The working performance of concrete is adjusted by modifying the ratio of tap water to ash or by adding a water-reducing agent [10, 11]. Based on relevant regulations and requirements, the mix proportions of recycled concrete are set according to the Common Concrete Mix Design Code and the High Performance Coagulation Application Technical Code (Table 1).

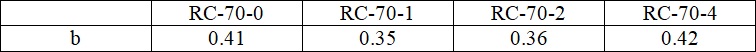

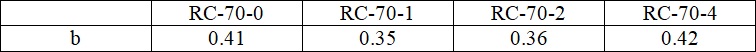

Table 1.

Mix ratio of recycled concrete

Source: The authors.

In Table 1, RC stands for recycled concrete, and 0, 1, 2 and 4 represent the corrosion degrees of the steel bars. The values 0, 30, 50, 70, and 100 correspond to substitution rates. Based on the mix ratio, the recycled concrete was prepared and cured for 28 days.

Treatment of steel corrosion

For a better pull-out experiment, the steel bars were treated via galvanizing and rusting [12, 13]. In general, the pH value of the void solution in concrete is greater than 7 when measured as described in reference 13, and a thin hydration oxide film of γ∙Fe2 O3∙nH20 will adhere to the surface of the steel. This oxide film plays a protective role, causing the steel bar to form a passivation state, which is referred to as the passivation film. If you want the passivation film to remain stable for a long time, the pH value of the solution must be high. If pH<11.5, the passivation film begins to be affected. If pH<9.8, the passivation film will be difficult to form, or the existing passivation film will gradually suffer erosion. Based on this principle, for the concrete reinforcement to rust, the following conditions must be met: 1. A potential difference must form on the surface of the reinforcement, creating battery corrosion; 2. The resistance of the electrolyte solution between the cathode and anode regions must be very small; 3. Under the influence of other factors, the passivation membrane initially formed on the steel bars will enter an activated state; 4. Whether it is a chemical reaction or the occurrence of ion diffusion, water and oxygen from outside the steel bar are required. The specific rusting process is as follows: First, the specimens in the curing room are soaked in a 5% NaCl solution for 4 days. Second, the connection line is established by connecting the corroded steel bars to the positive electrode of the experimental device and inserting a steel pipe into the solution, which is connected to the negative electrode of the experimental device. Finally, the current from the experimental power supply is adjusted to stabilize it at 0.05 A to form an electrolytic cell. Under the influence of the current, the steel bar loses electrons, which helps to achieve the anti-rust effect.

Bonding performance test

To test the adhesion between steel corrosion and recycled concrete under different corrosion degrees, an empirical study was conducted. The corrosion degrees are mainly divided into four categories based on corrosion rates of 0%, 1%, 2%, and 4%. There are three experimental methods: the first is to test the average bond stress of recycled coarse aggregate concrete, which is done through a slip experiment; the second is to test its peak tensile strength; and the third is to test the smoothness relationship.

Average bond stress-slip test

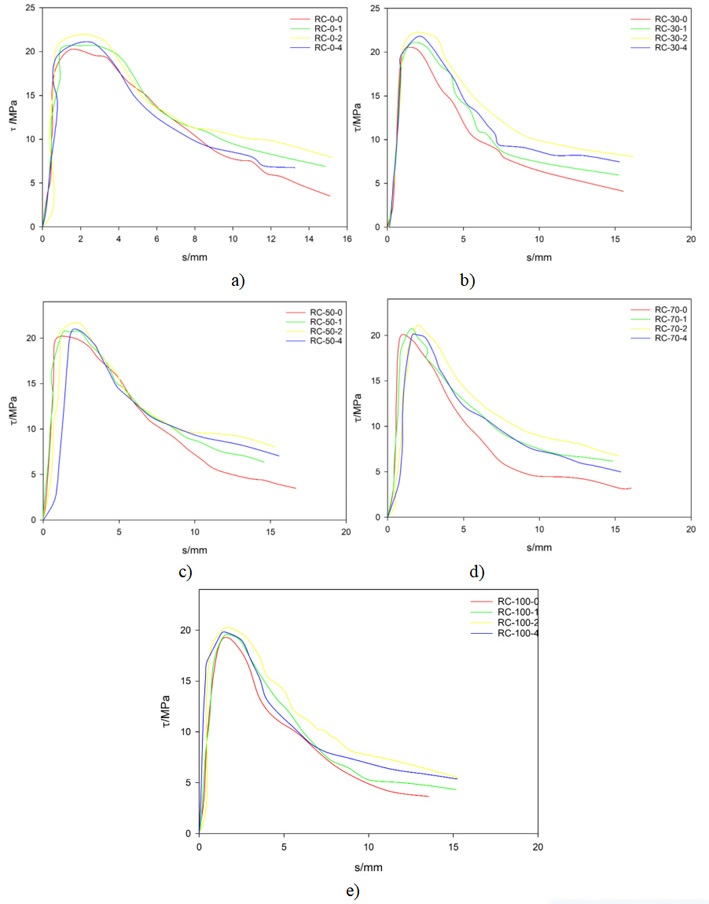

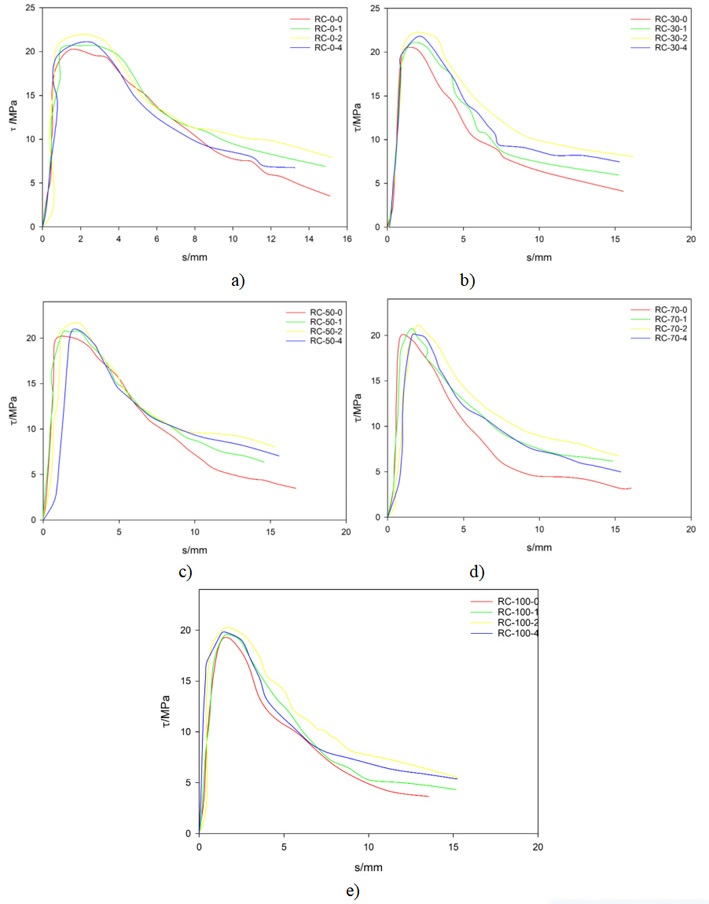

After experimentation, the corresponding slip curve of recycled concrete was obtained, as shown in Figure 1. In the resulting graph, the horizontal axis represents the average slip, and the vertical axis represents the average bond stress.

Figure 1.

Average bond stress‒slip curve of

reclaimed coarse aggregate concrete under different corrosion degrees

Figure 1.

Average bond stress‒slip curve of

reclaimed coarse aggregate concrete under different corrosion degrees

Source: The authors.

Where a) is the average bond stress when the replacement rate of recycled aggregate is 0%; b) is the average bond stress when the replacement rate of recycled aggregate is 30%; c) is the average bond stress when the replacement rate of recycled aggregate is 50%; d) is the average bond stress when the replacement rate of recycled aggregate is 70%; and e) is the average bond stress when the replacement rate of recycled aggregate is 100%. Based on the above results, the bonding stress clearly changes with the change of the corrosion degree of the steel bar. Specifically, as the degree of rust increases, the bond stress first increases but then decreases. When the degree of steel corrosion reaches 2%, the peak value of the average bonding stress reaches its maximum value. Compared with the recycled concrete with the 0% degree of corrosion, the average bonding stress is higher because the steel corrosion is lower. The gap between the steel bars and concrete gradually becomes smaller or is filled with trace rust products. This increases the roughness of the steel bar surface, thereby enhancing the friction between the two. In addition, the expansion of rust products, which compresses the surrounding concrete, increases the grip strength between the recycled concrete and steel bars. However, it weakens their bond and reduces the bonding strength of the concrete. Although the corrosion degree of the rebar is only 4% in the experiment, it can be inferred from the results that as the corrosion degree of the rebar is further increased, the average peak bond stress of recycled concrete will continue to decrease.

Peak tensile test

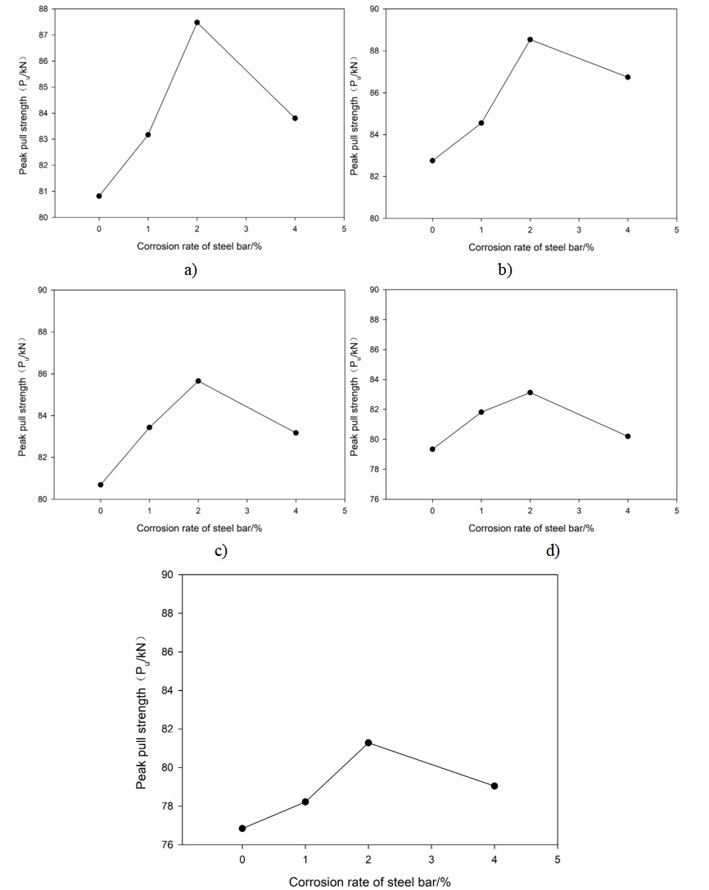

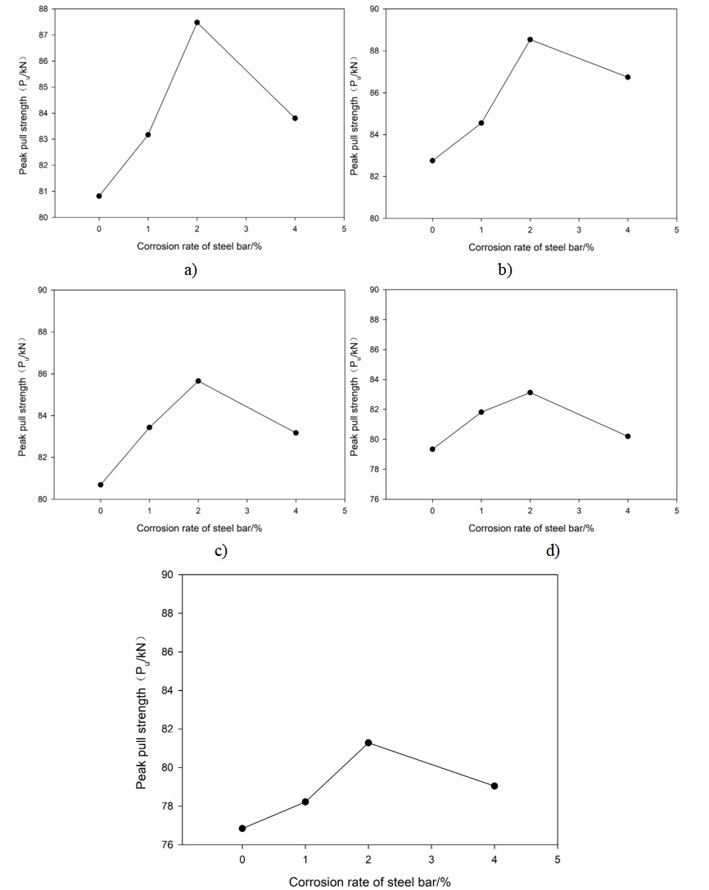

The peak tensile strength test was conducted to study the drawing performance of recycled concrete under different corrosion degrees of steel, and the results are shown in Figure 2.

Figure 2.

Influence of steel corrosion rate on the

peak tensile strength of recycled coarse aggregate concrete at different

replacement rates of recycled coarse aggregate

Figure 2.

Influence of steel corrosion rate on the

peak tensile strength of recycled coarse aggregate concrete at different

replacement rates of recycled coarse aggregate

Source: The authors.

Where, a) is the corrosion rate of the steel bar when the replacement rate of recycled aggregate is 0%; b) is the corrosion rate of the steel bar when the replacement rate of recycled aggregate is 30%; c) is the corrosion rate of the steel bar when the replacement rate of recycled aggregate is 50%; d) is the corrosion rate of the steel bar when the replacement rate of recycled aggregate is 70%; and e) is the corrosion rate of the steel bar when the replacement rate of recycled aggregate is 100%. Overall, the corrosion rate of steel bars can be determined by observing the horizontal axis in the graph, and the vertical axis represents the peak pull-out force. Under different recycled aggregate substitution rates, as the degree of steel corrosion increases, the corresponding tensile effect first increases but then decreases. When the corrosion degree is 2%, the peak pull-out strength of each group reaches its maximum value in the tensile test. When the regenerated coarse aggregate replacement rate is 0%, the maximum peak pull-out strength of the specimen with a 2% steel corrosion rate is 87.46 kN in the pull-out test. This value represents an 8.3% increase compared to that of the specimen without corrosion, and a 5.2% increase compared to that of the specimen with a 1% corrosion degree. When the regenerated coarse aggregate substitution rate reaches 100%, the maximum pulling force at a 2% corrosion degree is 81.3 kN. Compared with that of the specimen without corrosion, the pulling force increased by 5.7%, and when the corrosion rate was 1%, the pulling force increased by 3.8%. Considering that the regenerated coarse aggregate substitution rate is 100%, the relationship between the degree of rebar corrosion and the peak pull-out strength and bond stress of the regenerated concrete specimens is given in Table 2.

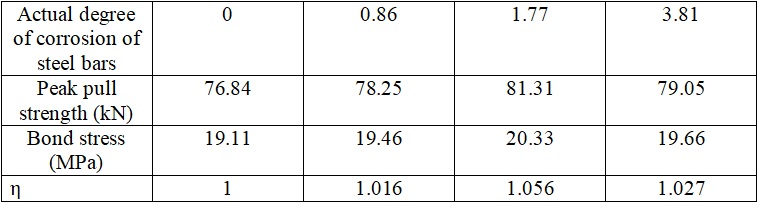

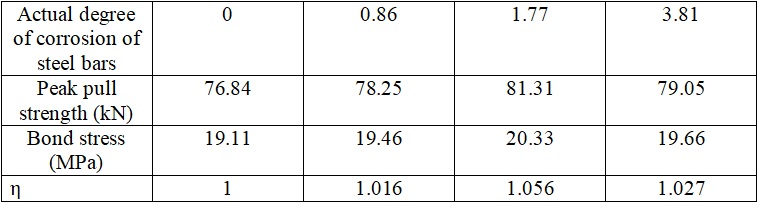

Table 2.

Relationship diagram

Source: The authors.

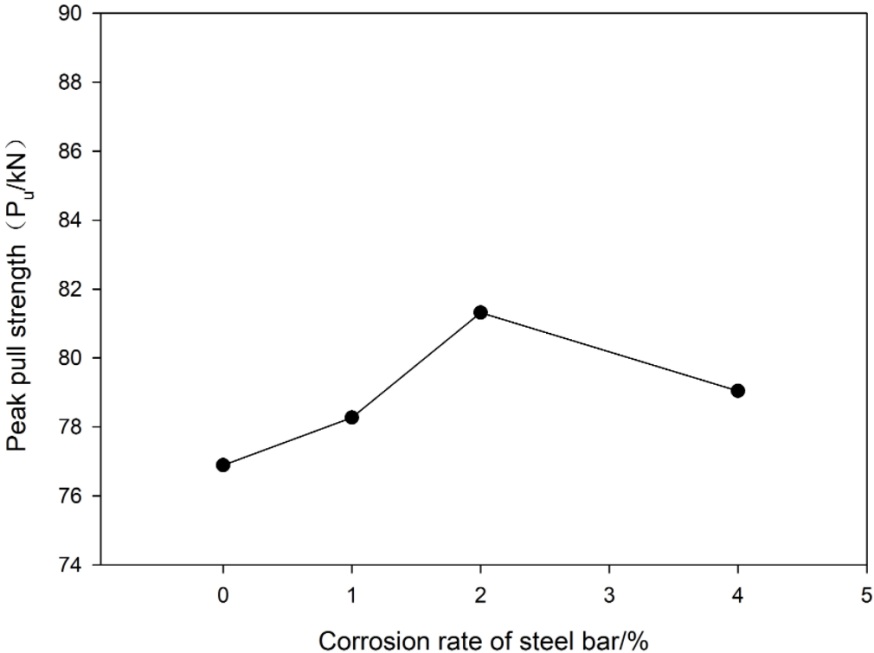

In Table 2, η represents the bond strength ratio, that is, the ratio of pull-out resistance with and without corrosion. According to Table 2, the tensile strength under different corrosion rates is shown in Figure 3.

Figure 3.

Pull-out resistance performance under

different corrosion rates

Figure 3.

Pull-out resistance performance under

different corrosion rates

Source: Authors’ own creation.

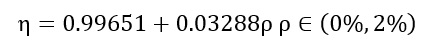

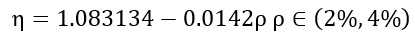

It can be seen that the peak pull-out strength first increases with the increase in steel corrosion degree, and then decreases. Based on the data in Table 2, the formula for the change in bond strength coefficient of recycled concrete with reinforcement corrosion can be fitted as follows:

In the above formula, p represents the degree of steel bar rust, and the η value under different p can be calculated using the formula. The peak pull-out force under any degree of steel bar rust can be calculated according to Pu

= η . Pu0

. Among these values, Pu0

indicates mild tensile strength, and Pu0

represents the peak pull-out strength of specimens with different degrees of rust.

Bond stress‒smoothing relationship

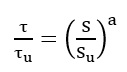

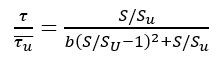

The shape distribution law is based on curves. The increasing segment of the curve is calculated based on the research results in reference [14], as follows:

The increasing segment of the curve is calculated based on the research results in reference [15], as follows:

In formulas (4) and (5), bond stress is represented by τ ; the average bond stress is represented by τu

; slip is represented by S; and the average peak slip is indicated by Su

. Taking the regenerated coarse aggregate replacement rates of 70% and 100% as examples, the data obtained from the drawing experiment were sorted and fitted. The value of parameter a in the above formulas was 0.65, and the value of parameter b is shown in Tables 3 and 4.

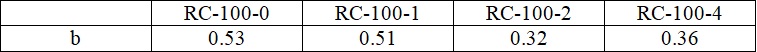

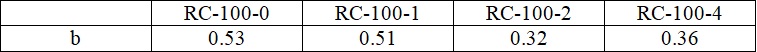

Table 3.

Values of parameter b under RC-70

conditions

Source: The authors.

Table 4.

Values of parameter b under RC-100

conditions

Source: The authors

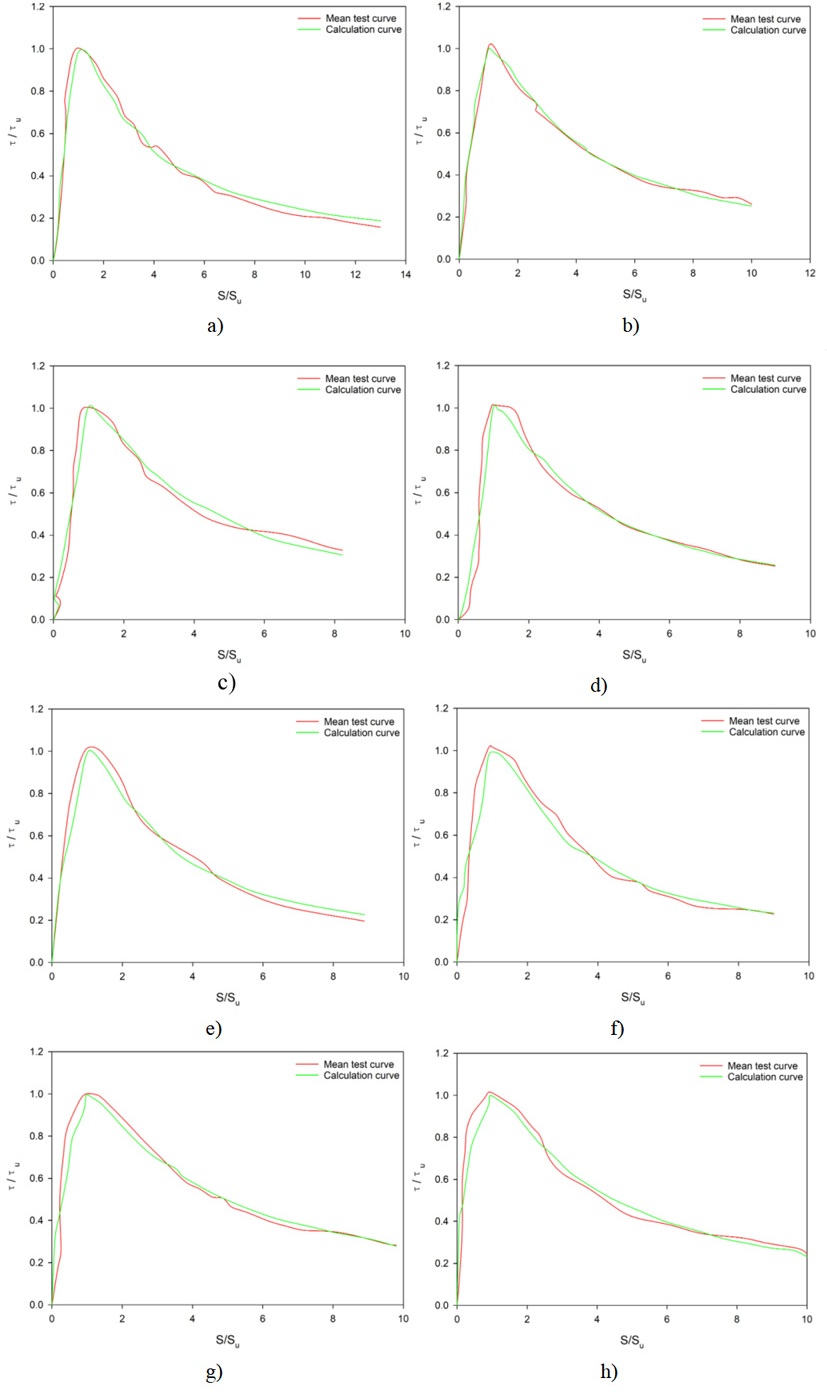

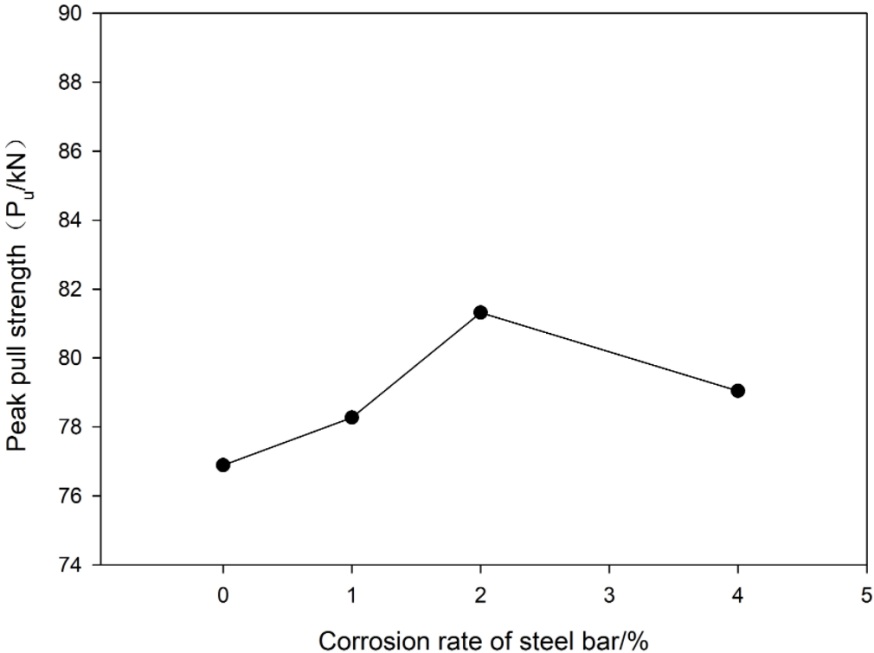

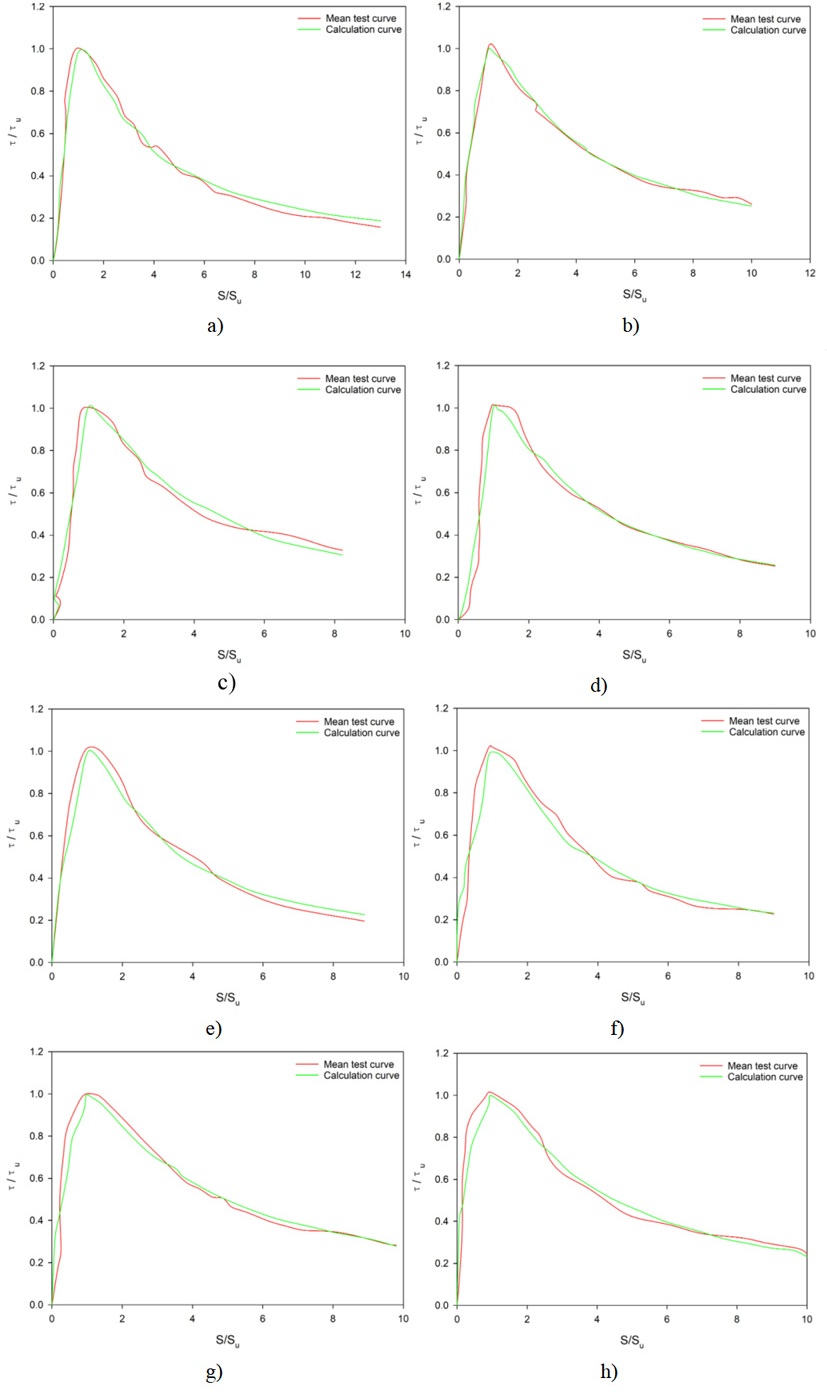

The results obtained from the bond stress‒smoothing relationship experiment are shown in Figure 4.

Figure 4.

Comparison between the experimental mean

value and the calculated value of the bond-slip curve.

Figure 4.

Comparison between the experimental mean

value and the calculated value of the bond-slip curve.

Source: Authors’ own creation.

Where a) is the RC-70-0 slip curve; b) is the RC-70-1 slip curve; c) is the RC-70-2 slip curve; d) is the RC-70-4 slip curve; e) is the RC-100-0 slip curve; f) is the RC-100-1 slip curve; g) is the slip curve of RC-100-2; and h is the RC-100-4 slip curve. In summary, the comparison between the experimental mean value and the calculated value of the bond slip curve shows a considerable matching effect, confirming the feasibility of formulas 4 and 5.

Analysis of overall experimental results

1. In the average adhesive stress experiment, the adhesive stress is observed by varying the degree of reinforcement rust. The results indicate that when the substitution rate remains constant, the peak value of the average adhesive stress first increases and then decreases with the increase in the degree of reinforcement rust, specifically between 0–2 s/mm. There is a sharp downward trend between 2–6 s/mm, and the downward trend becomes gentler after 6 s/mm. The maximum value of the average adhesive stress occurs when the corrosion rate is 2%, and all values fluctuate around this point. Therefore, in practice, by selecting different corrosion rates of steel bars, the bonding performance of recycled concrete can be regulated. To avoid deterioration from steel corrosion, when the degree of steel corrosion exceeds 4%, the average bond stress peak of recycled concrete will gradually decrease, and regular inspections should be conducted to prevent weakened recycled concrete performance due to excessive rusting. 2. In the experiment, research found that when both the degree of corrosion and the substitution rate of aggregates are changed simultaneously, the corresponding peak pull-out strength first increases and then decreases. Even if the substitution rate continues to increase, the drawing force reaches its maximum when the corrosion rate reaches 2%. For example, when there is a substitution rate of zero, the drawing force is 87.5 pu/kN. Under the condition of a 30% substitution rate, the drawing force is 88.5 Pu/KN. When the substitution rate is increased to 50%, the maximum peak pull-out strength is 85.6Pu/KN. At a 70% substitution rate, the drawing force is 83.1Pu/KN. When the substitution rate reaches 100%, the drawing force remains at 83.1Pu/KN. It is evident that the drawing force fluctuates between 83 and 89Pu/KN. Compared with that of the rusted recycled concrete, the peak tensile strength has improved, although the degree of improvement varies. 3. In the average slip experiment measuring the average bond stress between the rusted steel bar and recycled concrete, the data from the drawing experiment were fitted. In summary, if the substitution rate is constant, the average curves for recycled concrete with different corrosion degrees were generally consistent with the calculated curves, which confirmed the feasibility of the formula and the robustness of the research results presented in this paper, yielding considerable empirical results.

Conclusions

To better conduct this study and achieve the required degree of steel corrosion, the electric corrosion method was used to corrode steel bars. This approach helped to understand the bonding properties between various degrees of steel corrosion (0%, 1%, 2%, 4%) and recycled concrete, thereby facilitating subsequent empirical research. Through empirical research and analysis of the results, the following conclusions are obtained: 1. When the coarse aggregate substitution rate is constant, the peak tensile strength of recycled concrete initially increases and then decreases as the degree of steel corrosion increases. When the corrosion rate exceeds 4%, the decrease in peak tensile strength is greater. 2. When the replacement rate of recycled coarse aggregate is 30%, the peak pull-out strength of recycled concrete with a 2% steel corrosion rate is 6.9% higher than that of recycled concrete with a 0% corrosion rate. 3. By fitting the experimental data, the slip relationship of the average bond stress between the corroded steel bar and the recycled concrete under monotonic load is proposed, and the fitting effect of the recycled concrete under different degrees of corrosion of the steel bar is confirmed.

Acknowledgments

This

study was supported by Natural Science Foundation of Hubei Province

(2022CFB459).

References

[1] B. Lei, W. Yang, L. Yu, et al., “Evaluation of CO2 emission from carbonization of recycled concrete during its whole life cycle,” Concrete Cement Prod., no. 11, 2023, 82-87.

[2] W. Liu, “Study on the performance of recycled concrete prepared from waste building materials as aggregate,” Sichuan Cement, no. 09, 2023, 30-32.

[3] H. Qin, Z. Zhao, S. Ye, et al., “Experimental study on effect of steel fiber on compressive strength of recycled concrete,” Concrete, no. 06, 2023, 120-124.

[4] N. Bu, R. Liu, W. Fang, et al., “Study on mechanical properties and frost resistance of recycled concrete with fly ash for construction,” J. Funct. Mater., vol. 54, no. 05, 2023, 5223-5229.

[5] F. Yu, X. Zhu, D. Yao, et al., “Bond properties between self-compacting recycled concrete and ribbed steel,” J. Shenyang Univ. Technol., vol. 46, no. 03, 2024, 339-346.

[6] Y. Zhou, Y. Huang, F. Cao, et al., “Salt frozen erosion of stirrup constraints, the influence of recycled concrete with steel stick performance,” J. Build. Struct., vol. 44, no. S2, 2023, 438-446.

[7] B. González-Fonteboa, F. Martínez-Abella, C. L. Diego and S. Seara-Paz, “Stress-strain relationship in axial compression for concrete using recycled saturated coarse aggregate,” Constr. Build. Mater., vol. 25, 2011, 2335-2342

[8] W. Li, “Experimental study on Mechanical properties of recycled concrete,” Brick Tile, no. 04, 2024, 47-49.

[9] Q. Li and L. Wu, “Experimental study on the compressive strength of recycled concrete cubes by different mineral admixtures,” Constr. Supervis. Inspect. Cost, vol. 16, no. Z1, 2023, 10-14.

[10] T. Ren, “Research progress of preparation technology of recycled concrete,” Railw. Constr. Technol., no. 09, 2022, 46-49.

[11] H. Zhao, Y. K. Gao, G. Tian, et al., “Research and development status and review of recycled concrete,” Qinghai Transp. Sci. Technol., vol. 33, no. 03, 2021, 1-11+38.

[12] W. Yang, C. Jiang, J. Yang, et al., “Experimental study on corrosion efficiency of reinforced concrete with electrification,” Concrete World, no. 07, 2022, 10-13.

[13] J. R. Liu, H. S. Shang, W. Z. Wang, et al., “Corrosion current density and corrosion morphology of reinforced concrete,” Corros. Protect., vol. 42, no. 07, 2021, 34-37+41.

[14] M. H. Haraji, “Development splice strength of reinforcing bars em-bedded in pail and fiber reinforced concrete,” ACI Struct. J., vol. 91, no. 5, 1994, 511.

[15] Y. Chen, H. Shang, H. Feng, et al., “New type of reinforcement and concrete bonding constitutive relation of experimental study,” J. Build. Struct., vol. 53, no. 24, 2023, 62-67 + 117.

Notes

*

Research

article

Author notes

aCorresponding

author. E-mail: qs88422@163.com

Additional information

How to cite this article: Q. Su, “Research on the Bonding

Properties between Rebar and Recycled Concrete under Different Degrees of

Corrosion” Ing. Univ. vol. 29, 2025. https://doi.org/10.11144/Javeriana.iued29.rbpr

(1)

(1) (2)

(2) (4)

(4) (5)

(5)